Black epoxy sanding ramp

Basic Info

Model No.: KS

Product Description

Product description:

Black epoxy sanding ramp Product Overview:

Epoxy resin sanding and anti-slip floor is made of imported epoxy resin and curing agent and

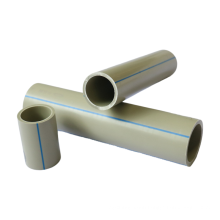

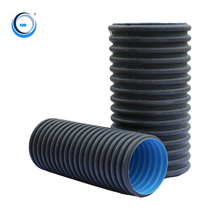

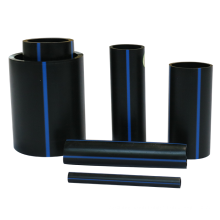

added with appropriate amount of filler. hdpe pipe for water supply,Black Water Supply Hdpe

Pipes,It can meet the requirements of anti-slip property on the ground by choosing different

performance fillers.Self Leveling Cement Floor,Self Leveling Cement Floor(KS-SZ).

Clear Epoxy For Concretev

Application area:

Black Epoxy Slide Material Application scope:

Epoxy resin sanding and anti-slip floor is made of imported epoxy resin and curing agent and

added with appropriate amount of filler. Hdpe Water Supply Plastic Pipe,It can meet the

requirements of anti-slip property on the ground by choosing different performance fillers.

Cement Self-leveling Base Floor,Cement Self-leveling Floor.

Grouting Material

Product features:

Black Epoxy Anti-slip Sanding Ramp Product Features:

- Rough surface, no slip, no sand, good anti-slip function

- excellent anti-corrosion mold, acid, alkali, salt corrosion, non-toxic side effects

- excellent wear resistance, impact resistance, seamless, dustproof and waterproof, easy to clean

- excellent adhesion, rich colors, provide standard colors and customer set color

Construction instruction:

Epoxy Flat Ground And Mortar Floor Construction process:

1, the original ground treatment: the construction of the ground to carry out a full grinding, repair, dust2, base coating: the primer material with roller or trowel

3.Mid-coating: After the primer curing, grinding, dusting, and using a trowel to draw a good middle layer material

4.Sanding: Mix the sand, no accumulated sand

5. Top coat: Roll the top coat material onto the middle coat

Conservation:

1. The floor should be maintained for 7-10 days after construction is completed and put into use. During the

maintenance period, water or other solutions should be prevented from invading the surface;

2. Every employee who enters the workshop must be replaced with a coke-soled shoes;3. All hardware: can not get in the above;

4. Pull the board to fully lift the pallet off the ground. When turning, pay special attention to the corner of the

board. Do not scratch the ground.

5. When cleaning the floor, use a soft mop with good water absorption or a wet or dry vacuum cleaner, which

can be cleaned with clean water or detergent;

6. If it is worn or scratched due to a long time of use, a small area can be repaired. If the area is large, it is

recommended to re-roll once.

7. Before the equipment enters the factory, lay a hard carton bottom on the floor to avoid scratching the ground

during the transportation of equipment;

8. Carts, cart wheels, please use rigid or elastic tires.Basic Cement Self-leveling Floor.

Product Categories : Epoxy Floor Coating System > Epoxy Flat Ground And Mortar Floor